Burned-out floodlight bulbs aren’t just an inconvenience—they’re a risk to safety, a drain on your wallet, and a source of avoidable headaches. Taking action today can make your lighting system perform better, save you money in the long run, and prevent future issues. So, what’s causing the problem, and how can you fix it?

The failure of floodlight chips can be traced to several common culprits, including power surges, excessive heat, or subpar components. Overheating—often caused by poor heat dissipation—takes a toll on LED chips, while voltage fluctuations can wreak havoc by overloading the circuitry. Additionally, manufacturing defects, mismatched materials, and natural wear and tear over time can lead to chip failure. Environmental factors like extreme weather or moisture can also accelerate the damage. To tackle these challenges, prioritize investing in high-quality LED floodlights built for durability. Make sure they’re installed correctly, and don’t overlook regular maintenance to keep them in top shape.

Ready to dig deeper into the root causes and solutions? Let’s explore how you can keep your floodlights running flawlessly.

What Are the Common Causes of LED Chip Failure?

LED chip failure is often caused by a combination of design flaws, environmental factors, and operational challenges. Here’s a breakdown of the main culprits:

1. Heat-Related Issues

Excessive heat is one of the biggest threats to LED chip longevity:

– Thermal Stress: High temperatures cause the epoxy resin package to expand rapidly, which can weaken or tear the bonded contacts.

– Poor Heat Dissipation: Without effective heat sinks or proper ventilation, thermal degradation occurs faster, reducing the lifespan of the chip.

Solution: Ensure adequate heat dissipation using well-designed heat sinks and proper ventilation.

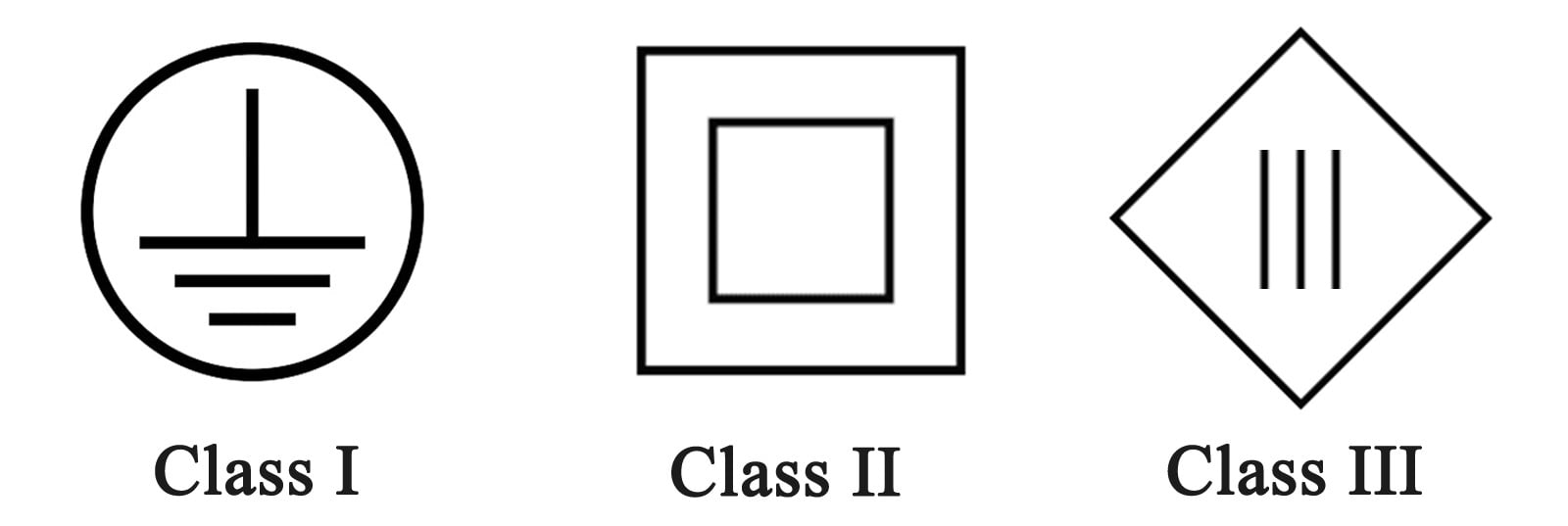

2. Electrical Stress

Electrical irregularities can severely impact LED performance:

– Electrical Overstress (EOS): Voltage surges overload LED chips, causing them to burn out.

– Electrostatic Discharge (ESD): The small distance between electrodes in LED chips makes them vulnerable to damage from static electricity.

Solution: Use protective circuitry and follow proper handling protocols during installation and maintenance.

Typical LED Chips Electrical Parameters

3. Manufacturing Defects

Production-related flaws can result in early chip failure:

– Epitaxial Defects: Impurities during crystal growth can hinder proper semiconductor nucleation.

– Chemical Residues: Residual chemicals left during processing may cause electrochemical reactions.

– Physical Damage: Mishandling during production, like scratches or clip marks, can compromise chip integrity.

Solution: Source LED chips from reputable manufacturers with stringent quality controls.

4. Material Incompatibility

Material mismatches can lead to corrosion or long-term damage:

– Aluminum Electrodes: Some modern LED chips use aluminum electrodes that can corrode when exposed to chlorine-containing packaging materials.

Solution: Ensure material compatibility during design and manufacturing to prevent chemical reactions.

5. Degradation Over Time

Even high-quality LEDs experience natural wear and tear:

– Current Crowding: Uneven current flow causes localized overheating, leading to reduced efficiency and brightness.

– Electromigration: High electrical currents displace metal atoms, weakening connections over time.

– Phosphor Degeneration: Heat and UV exposure degrade the phosphor layer, reducing brightness and altering light color.

Solution: Maintain proper operating conditions to minimize stress and slow degradation.

LED Chips Luminous Flux vs Time

6. Environmental Factors

Harsh environments can accelerate LED chip failure:

– Moisture and Corrosion: Humidity, sulfur-containing atmospheres, or acidic environments can damage components and lead to abnormal deterioration.

Solution: Use LEDs designed for tough environmental conditions, with robust sealing and corrosion-resistant materials.

Diagnostic Tips for Dead LED Flood Light Chips

Troubleshooting dead LED flood light chips requires a systematic approach to identify the root cause of the failure. Follow these steps to pinpoint and resolve issues:

1. Visual Inspection

Start by checking for obvious signs of damage:

– Look for burn marks or discoloration on the chip surface.

– Inspect for cracks in the epoxy resin or protective casing.

– Check for corrosion or damage to solder joints and connections.

– Examine the LED driver for issues like swollen or leaking capacitors and loose or broken wires.

2. Test the Power Supply

Use a multimeter to verify the power supply’s output voltage:

– Ensure the voltage aligns with the LED chip’s specifications.

– Check for voltage fluctuations or irregularities that could indicate a failing driver.

– If the power supply is faulty, replace it and retest the light.

3. Continuity Check

With a multimeter set to continuity mode:

– Test connections between the LED chip and the driver.

– Ensure all solder points and connectors are secure and free from damage.

4. Inspect for Overheating Issues

Heat damage can often be the culprit:

– Look for signs like deformed housing or melted components.

– Check for burnt-out LEDs, which may appear blackened or dim.

– Ensure the heat sink is properly attached and functioning to dissipate heat effectively.

5. Test Individual LEDs

For multi-LED chips, test each LED using a multimeter or LED tester:

– Identify any failed LEDs that do not light up or show reduced brightness.

– Remember, one dead LED in a series circuit can cause the entire chip to fail.

6. Check for Electrical Overstress (EOS) or Electrostatic Discharge (ESD) Damage

Inspect for signs of damage from power surges:

– Look for burn marks or damaged traces on the circuit board.

– Verify that the light fixture is equipped with proper surge protection.

7. Moisture or Corrosion Inspection

Examine the light for water ingress or moisture buildup:

– Check for corrosion on the chip, wiring, or circuit board.

– Replace any damaged components and improve the fixture’s sealing to prevent future water damage.

8. Replace or Repair

If specific components are identified as failed:

– Replace damaged LEDs or the entire chip as needed.

– Repair damaged solder points or connectors.

– If the root cause cannot be identified or repaired, consider replacing the entire flood light fixture.

FAQs About LED Flood Lights

Can Flood Lights Be Repaired?

Yes, flood lights can often be repaired. Issues like loose connections or a faulty driver are relatively simple and inexpensive to fix compared to replacing the entire light. However, more serious problems, such as a damaged LED chip, may require professional assistance. Always consult a technician to ensure safety and avoid wasting money.

Can You Change the Bulb in an LED Flood Light?

LED flood lights don’t use traditional bulbs; they use chips. If a chip fails, you may need to replace the whole fixture unless it’s designed to allow chip or driver replacement. Quality LED fixtures usually come with warranties, so check your options before making any decisions.

Do Flood Lights Burn Out?

Yes, but it’s less common with LED flood lights compared to traditional lights. While halogen bulbs burn out due to filament failure, LED lights are more durable. They can still fail due to power surges, overheating, or low-quality components. Proper care and high-quality products reduce the likelihood of burnouts.

How Many Years Do Flood Lights Last?

LED flood lights typically last 30,000 to 50,000 hours, which translates to about 7 to 15 years of regular use. Lifespan depends on the quality of the components, proper installation, and usage. Managing heat and preventing power surges can further extend their life.

Why Would a Flood Light Stop Working?

Flood lights can fail for various reasons, including blown fuses, damaged wiring, faulty drivers or chips, moisture intrusion, or dust buildup. Electrical issues or environmental factors are often the root causes.

How Much Does It Cost to Replace Flood Lights?

Costs vary widely depending on the type of light. LED flood lights can range from $50 to $500. While they cost more upfront, they save money over time due to lower energy use and longer lifespans. Installation costs vary, and professional help may be necessary.

Why Do LED Flood Lights Go Bad?

LED flood lights fail due to power surges, overheating, exposure to harsh weather, or poor-quality components like chips or drivers. To prevent these issues, prioritize proper maintenance, installation, and purchasing high-quality products.

Why Is Part of My Flood Light Chip Dead?

If part of the LED chip is dead, it’s often due to a single LED failure in a series circuit, which can disrupt the entire fixture. Identifying and replacing the faulty chip or component may resolve the issue.

Do You Need an Electrician to Install a Flood Light?

Yes, especially if wiring is required. An electrician ensures safe installation, compliance with electrical codes, and proper mounting. DIY installation can lead to issues like poor connections or improper setup.

Why Is My LED Flood Light Suddenly Dim?

Dimming may result from power supply issues, aging chips, a failing driver, or dirt and debris on the light’s surface. Cleaning the light and checking the power supply are good first steps. If the issue persists, consult a technician.

Can I Replace Flood Lights with LED?

Yes, and it’s a smart choice. LED flood lights are more energy-efficient, longer-lasting, and provide better lighting. Ensure the new fixtures are compatible with your setup, or seek professional installation help.

How Often Should I Replace Flood Lights?

LED flood lights usually last 7 to 15 years, while traditional lights may need replacement every 1 to 3 years. Monitor their performance and replace them as needed.

What Is the Life Expectancy of Outdoor Lights?

Outdoor LED lights typically last 30,000 to 50,000 hours under normal conditions. Longevity depends on product quality, usage, and maintenance. Keep the lights clean and shielded from water and dust for maximum lifespan.

Why Do LED Flood Lights Fail So Quickly?

Early failures occur due to overheating, poor-quality components, power surges, or improper installation. To avoid these issues, invest in high-quality fixtures and ensure proper installation and maintenance.

Conclusion

Flood light chip failures are costly and inconvenient but preventable. Invest in reliable, high-quality products, maintain them regularly, and hire professionals for installation. If you’re looking for durable, customizable LED flood lights, Logos Lighting offers top-notch solutions. For assistance or inquiries, contact us directly—our lighting experts are here to help!

Get an Instant Quote Now

Let us help you get started with our superior LED lighting products.

Our LED Lighting experts can help to solve your issues.

Before sending your message, please note:

Your message goes to Logos Lighting and it may take time to reply to you.

Please complete all fields unless otherwise indicated. This will help us deal with your inquiry more efficiently. Alternatively, you can contact us directly via email: info@logosled.com.